Product

Stainless Steel Casting- Investment Casting Parts manufacturer

Custom stainless steel parts manufacturer, Investment casting process

Ever Famous Co., Ltd. is a leading stainless steel parts manufacturer based in Taiwan, offering top-quality OEM investment casting metal parts and custom stainless steel parts for a range of industries. As an ISO 9001 verified manufacturer, we pride ourselves on delivering high-precision stainless steel components and custom investment casting parts tailored to meet the specific needs of our global clientele.

Our Expertise:

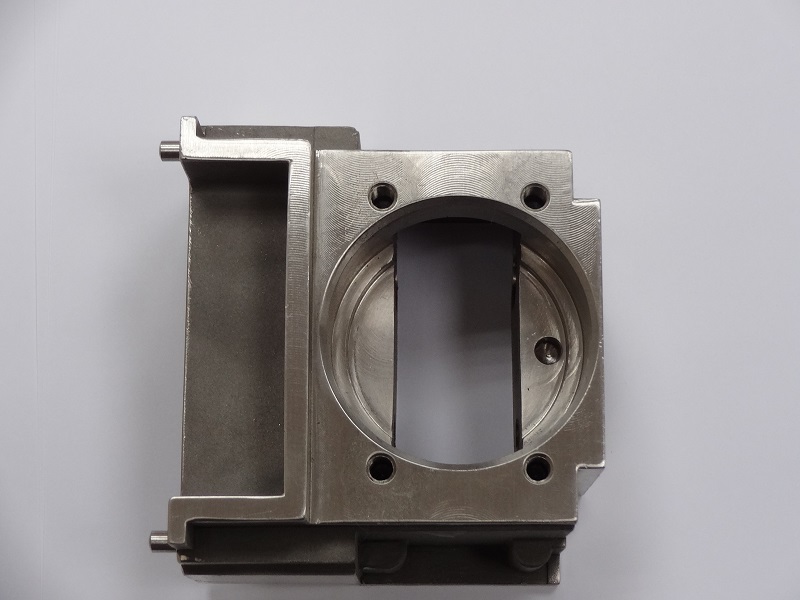

- Stainless Steel Precision Parts: We specialize in producing stainless steel precision parts with exceptional accuracy and durability. Our components are widely used in various sectors such as automotive, aerospace, and industrial equipment.

- Custom Molds and Investment Casting Parts: As a custom stainless steel parts manufacturer, we offer OEM/ODM services, including the design and production of custom molds and parts through investment casting. Our investment casting stainless steel parts are known for their excellent surface finish and strength.

- CNC Machining and Surface Finishing Services: Our comprehensive manufacturing services cover everything from casting fabrication, CNC machining, and surface finishing to more advanced processes like plating, painting, coating, and powder coating. These capabilities ensure that every product meets the highest standards of quality and performance.

Why Choose Us:

- ISO 9001 Certified Quality: Our commitment to quality is backed by ISO 9001 certification, ensuring that every product is manufactured to meet strict quality control standards.

- Taiwan-Based Stainless Steel Factory: As a stainless steel factory from Taiwan, we offer reliable, cost-effective production with fast lead times for international customers.

- OEM/ODM Solutions: We provide full OEM/ODM services, including custom mold design and manufacturing for investment casting and CNC machining parts, catering to a wide range of custom needs.

Whether you're looking for a high-quality stainless steel parts manufacturer in Taiwan or an investment casting parts factory direct supplier, our expertise and dedication to excellence make us your ideal partner for all your metal component needs.

Ever Famous company is OEM investment casting metal parts/ Lost wax casting parts / stainless steel 306 products manufacturer.

Capability and Specifications

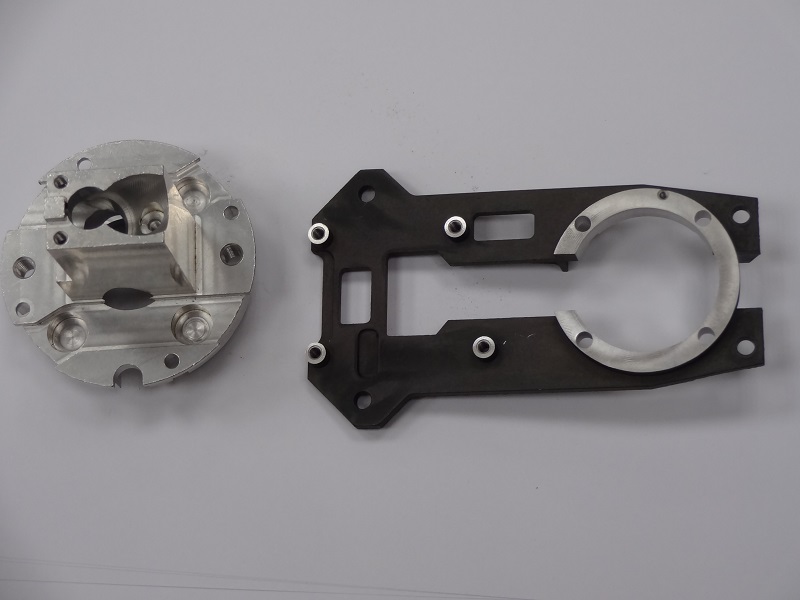

Investment casting metal parts

Material: Carbon steel, stainless steel, duplex stainless steel…etc.

Per customer's drawing and requirements

Quality guarantee and on time delivery

- Investment casting metal parts

- Weight: 0.1 to 10kg

- Used in metallurgy, automobile, aero, chemical, ship hardware and other engineering industry

- Other processes: sand casting, die casting, lost-foam casting and permanent mold casting

- Materials: ductile cast iron, carbon steel, steel alloy, stainless steel, brass, aluminum

- Design and production as per customer's requirement

- Short delivery time for both samples and orders

- Process description:

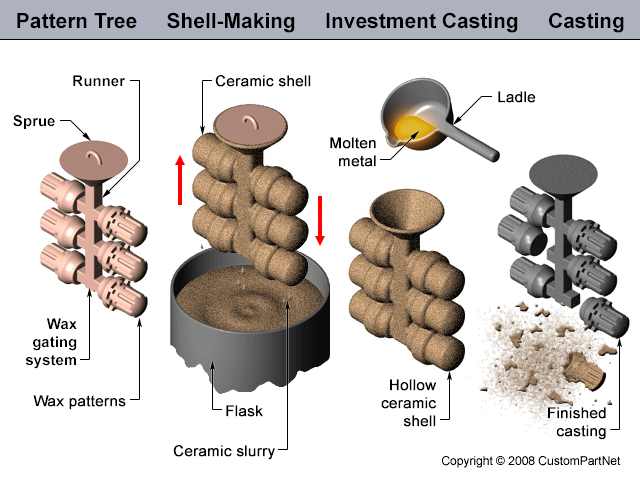

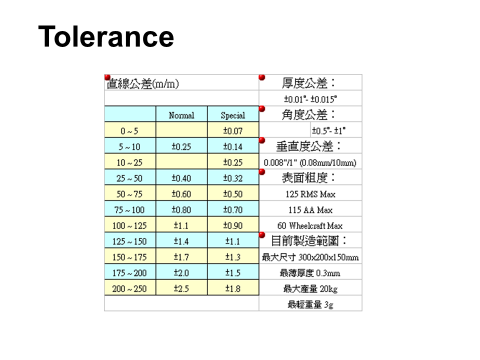

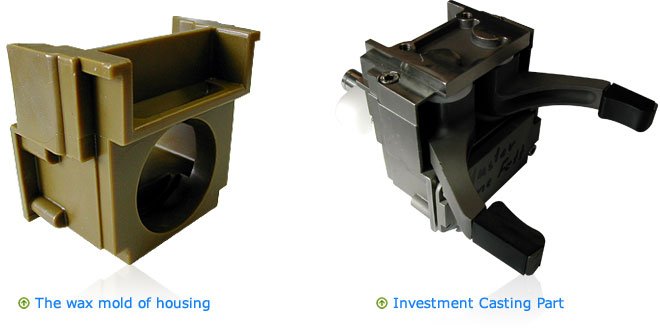

We offer custom investment casting parts, lost wax casting metal parts, to our customer. This lost wax casting process makes shell mold for metal parts. This process is used to cast complex high quality parts with requirements of a very good surface finish and close dimensional tolerances.

A wide range of alloys is available for investment casting process. They include carbon steels, low alloy steels, stainless steels, tool steels and copper based alloys. The investment cast parts can range from a weight of just a few ounces to approximately 80 pounds. If you are concerned with precision in very small parts, we are especially proficient at very fine detail work including teeth and serrations.

First article layouts and spectrometer material certifications are provided with all first article samples.

A variety of secondary operations can be performed on investment castings. They include heat treatment, machining, plating, painting, polishing and buffing, assembly services and even custom packaging.

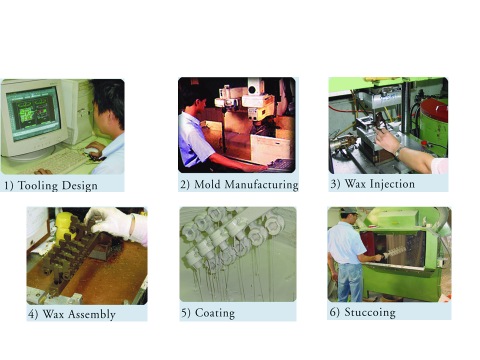

Investment casting parts process

- We are the manufacturer of lost wax casting, also known as investment casting parts.

- We make investment casting moulds (molds), investment casting tooling design, investment casting tooling manufacturing, wax mold injection, wax assembly, shell mold, and investment casting parts.

- Our process including investment casting de-waxing, investment casting sinitering, investment casting, wax casting mold removal, lost wax casting cutting.

Material for investment casting materials are Aluminum alloys, Bronzes, tool steels, stainless steels, haste alloys, and precious metals. Parts made with investment casting often do not require any further machining, because of the close tolerances that can be achieved.- Our investment castings use in many industries—agriculture, automotive, electronics, firearms, gas, hardware, high-tech, sporting—have benefited from each of their lost wax casting purchase orders.

- Our products include aluminum investment castings, titanium lost wax castings, stainless steel investment casting parts. We make investment casting parts with the alloy that will best meet your requests.

- Alloy Specifications of lost wax casting: Carbon steel, Low and High Alloy Stainless Steel, SG iron, Cast Iron, Copper and Copper Alloys, Aluminum and Aluminum Alloys, Cobalt and Nickel based Alloys etc.

Stainless Steel Castings and Products

Computer Parts

Weapon Parts

Automotive Parts

Sewing Machine Parts

Microware Parts

Medical & Dental Parts

Machinery Parts

Hardware Parts

Equipment

Wax injection machine

Coating system

Shell convey system

Shot Tumblast

Hanging Type Shot Blasting Machine

Sintering oven

Shell vibration machine

High frequency induction furnace

Grinder

Automatic sand blasting machine

Barrel Type Shot Blasting Machine

Capacities: 700k pcs/M

Our Policy

Innovation and developing in Technique

High level of expertise

Outstanding quality

On-time delivery to customer needs

“We value Customer Satisfaction”